PLC Programming

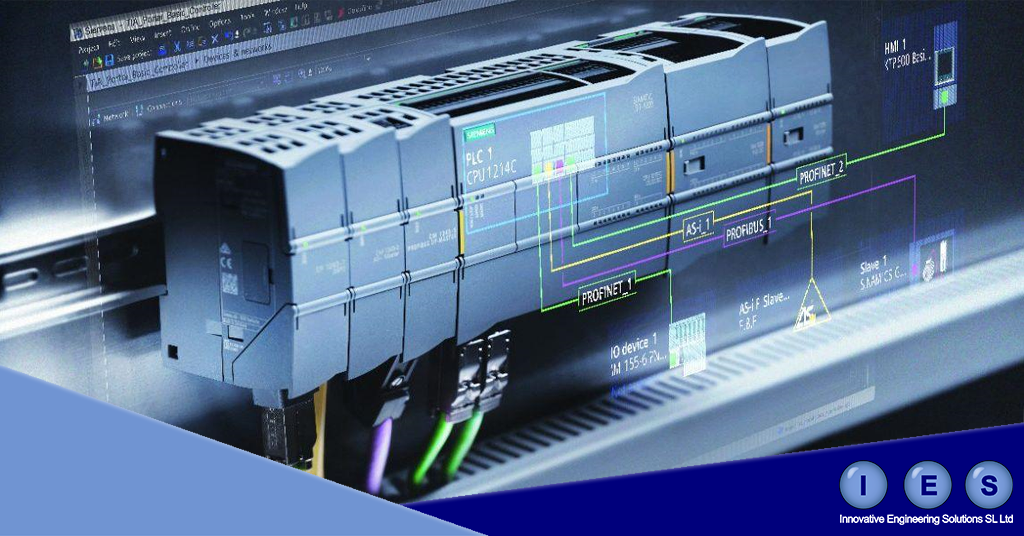

IES are specialists when it comes to installing PLC controllers and programming them to work with all kinds of industrial machinery.

Our specialised team have years of experience within the engineering industry specifying and installing these units, so if you want a quality result and a reasonable price, look no further and contact our Automation and PLC programming team today, we’ll be more than happy to assist you with your project. Send us your enquiry here

What is a PLC (Programmable Logic Controller) ?

A Programmable Logic Controller (PLC) is a type of computer-based industrial control system that is used for controlling various processes and machines in industries such as manufacturing, oil and gas, power generation, and others. It is designed to replace traditional electromechanical systems with a more flexible, reliable and efficient solution.

PLCs are programmable devices that can be programmed using various programming languages to perform specific control functions. They receive inputs from sensors and other input devices, process the information, and then control various outputs, such as actuators or control devices. The outputs are used to control various processes or machines in real-time, making the system highly responsive and efficient.

In summary, PLCs are essential components in modern automation systems and play a crucial role in optimizing industrial processes and improving overall efficiency.

What is the difference between the different types of PLC Controllers on the market?

There are many manufacturers of Programmable Logic Controllers (PLCs), some of the most well-known ones include:

- Allen-Bradley (Rockwell Automation)

- Siemens

- Schneider Electric

- ABB

- Mitsubishi Electric

- Omron

- General Electric (GE)

- Beckhoff Automation

- Bosch Rexroth

- Wago

The differences between these manufacturers can be seen in the following areas:

- Features and capabilities: Different PLC manufacturers offer different features and capabilities, such as number of inputs and outputs, communication protocols supported, and software compatibility.

- Price: The cost of PLCs can vary widely between manufacturers, with some being more expensive than others. This can be due to differences in features and capabilities, as well as brand reputation and market positioning.

- Ease of use: Some PLCs are easier to program and use than others, depending on the manufacturer. Some manufacturers offer more user-friendly software and documentation, while others may be more technical in nature.

- Reliability: Different PLCs may have different levels of reliability, depending on the manufacturer and the specific model. Some manufacturers have a reputation for producing high-quality, reliable PLCs, while others may have a less favorable reputation in this area.

- Support and after-sales service: The level of support and after-sales service offered by different PLC manufacturers can vary greatly. Some manufacturers have a large network of distributors and service centers, while others may be more limited in this area.

In conclusion, the choice of PLC manufacturer depends on the specific requirements of your application, including the level of complexity, budget, and desired features and capabilities.

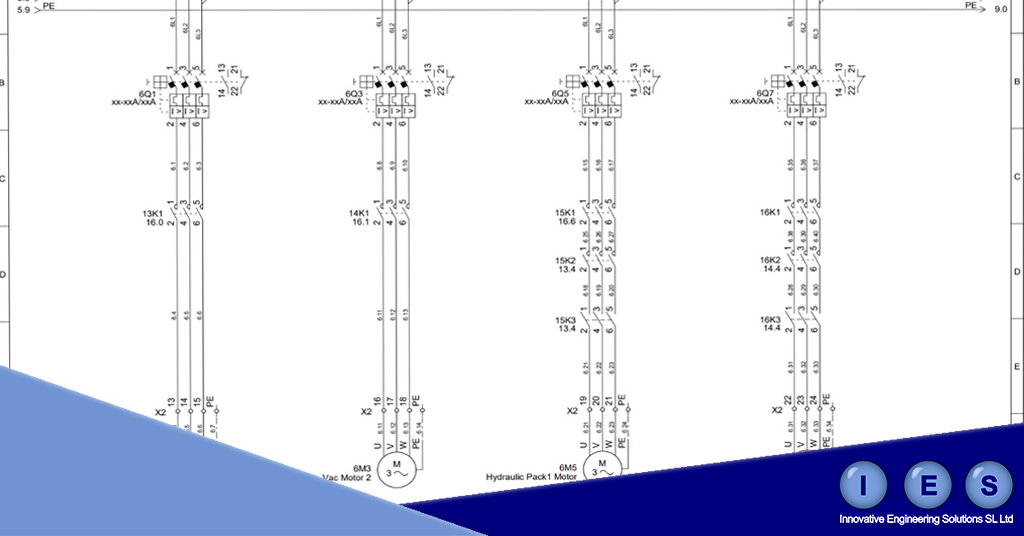

PLC Programming and the service we offer.

Our company offers professional PLC programming services, which help businesses automate and optimize their operations.

Our experienced engineers have a deep understanding of the latest PLC technologies and use state-of-the-art programming tools to create custom PLC programs tailored to meet the specific needs of our clients.

Whether you need to upgrade an existing system or design a new one from scratch, our team will work with you every step of the way to ensure that the end result meets your expectations and delivers the desired results.

With our PLC programming services, you can benefit from increased efficiency, improved accuracy, and enhanced productivity in your operations.

Contact our team here to discuss your requirements in more detail and we should be able to help you.

Innovative Engineering Solutions (SL) Ltd. Registered in the United Kingdom

Company No: 11861222 – Auto Evolution Building – Newington, Sittingbourne. Kent. ME9 7PE